This is the last part of my 3D printing saga. Recall that I first dabbled in 3D printing to get a Homo naledi skull replica for the anthropology department at Grossmont College. While work on that area went on its own path, I used 3D printing for my own goals. My personal projects wrapped up before the Homo naledi skull since the latter project was far larger and more complicated than the busts that I made. I am happy that the work on the H. naledi skull reached its own happy end with the production of two life-sized replicas.

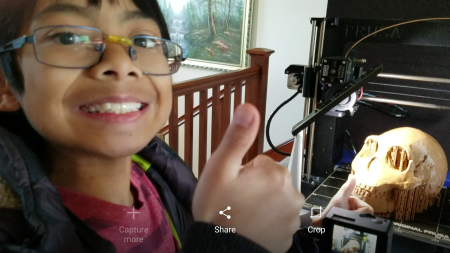

When we left the Homo naledi replica story, I had sent the hollowed 3D file off to a local printer whom I found on the 3D Hubs site. The skull has a lot of fine details and irregularities that demanded a lot of 3D printing expertise. Browsing the local printers, I found one whom I could trust to get the print done without giving up. The printer I chose was Brother Robot, or Calramon Mabalot. He is a ten-year-old who built his first printer two years prior and has made very detailed 3D selfies of customers, an articulated prosthetic hand, and quadcopters.

Brother Robot eagerly took the challenge and worked through many obstacles in producing the Homo naledi skull. Reduced-scale prototypes showed that the model was stable, but the full-sized version encountered several false starts due to printer issues (remember what I said about current 3D printing technology).

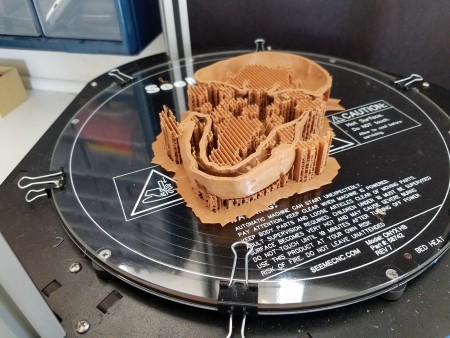

{ Caption: First print attempt, showing the breakaway support structure inside and out. Photo by Brother Robot. }

One promising attempt hit a snag common to printers of all types: running out of material right before completion!

{ Caption: Almost there! Aaaand, out of filament. I here this one is now a pencil cup. Photo by Brother Robot. }

Brother Robot eventually used the Homo naledi print to christen a new advanced printer that he had built, and it worked perfectly.

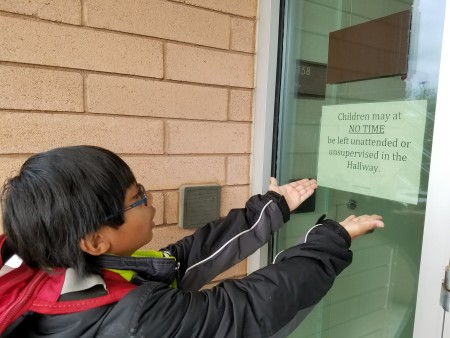

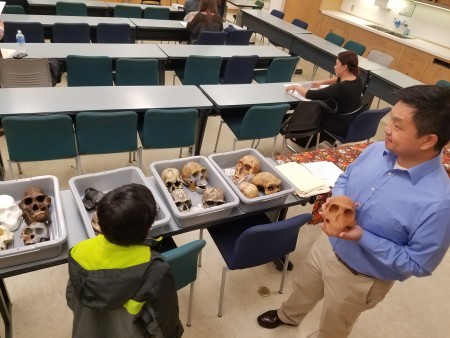

The end of a 3D Hubs transaction usually involves picking up the print at the printer’s doorstep without ever meeting in person, but that seemed like an ignominious end for such a demanding project. We thought a better conclusion would be to show the classroom where the replica would be used, along with the other pieces that we have. Calramon documented his visit on his Twitter:

🔎Project Study: Delivering the Homo Naledi #3dprinted Skulls to the @Grossmontedu Anthropology Department where it will join the collection! pic.twitter.com/oMaTZqNMHy

— Calramon Mabalot (@HabSkibbix) March 22, 2017

As the end of my 3D printing adventure (for now), I was delighted with everything at the end. I made a few busts for me and some friends, and educational replicas for one of my colleges. I look forward to a time when 3D printing will be as easy and convenient as printing a photograph today. I am very thankful for those who have taken the plunge into this hobby today for the effort they put into this demanding craft.